Future Reciprocating Engine, 120% torque improvement. 50% GHG reduction. A great innovation in 150 years of internal combustion engine development.

Multi-fuel, no engine knocking, best for most types of fossil fuel and bio-fuel. Ultra low emission (or carbon neutral ) when burns ethanol or H2. Mileage is doubled in comparison to existing ICE combustion technology for most types of fuels.

| Outcomes (comp. to prior art) | Measures taken in new engine |

| Output torque increased by >120% at same cylinder pressure. (@compression ratio11:1). | Keep combustion volume constant from 0 to 40°ATDC. Make peak combustion pressure at 42°ATDC |

| Knocking reduced or eliminated | Combustion is started after TDC |

| Engine material /volume reduced by 50% | Torque on crankshaft is doubled at same cylinder pressure |

| Fuel efficiency doubled, >220% in mileages per gallon | Torque on crankshaft torque doubled at same amount of fuel |

| Use existing parts and manufacturing processes | Similar piston/crankshaft mechanisms as in prior art |

| Multi-fuel available in one engine | Fuel is injected after TDC position, fuel is not restricted by compression ratio. |

Is it too good to be true?

Future of piston engine, 220% in mileages per gallon when burns gasoline.

How does the engine work? Watch the video.

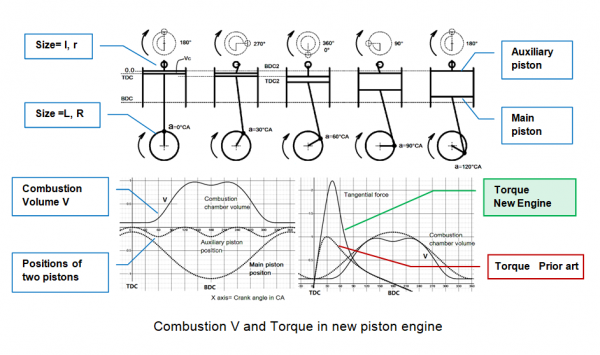

**Note 1, animation. New Engine Animation: Comparisons of combustion chamber volumes and instant torques. The animation shows different output torques when combustions are located at different crank angles, and the unique Peak Torque is located at exact 42˚ATDC position.

Over the past 150 years, there has been a profound improvement in all aspects of piston engines, but the fuel efficiency on crankshaft is still lower than 40%. Diesel and gasoline piston engines account more than 14% GHG emission (1400 million metric tons) worldwide in transportation only. However, almost all conventional piston engines have a similar profile in combustion chamber volume, and essential modifications have to be made.

Our study shows that the output torque on crankshaft can be increased significantly in certain combustion chamber topology with retarded control of injection and ignition, and there is a great potential to double or even triple the fuel efficiency in 2500rpm and below.

And the engine effective output is decided by both combustion chamber volume (V) and tangential force converting ratio (Cr) at the monument the peak combustion pressure occurs. In the new topology, the minimum (or clearance) combustion chamber volume is extended from 0˚TDC to 40˚ATDC, and injection and ignition are retarded to make the peak combustion take place at 42˚ATDC, this results a torque increase by 120% at 2,500rpm or >300% at 800rpm when burns gasoline (@ compression ratio of 11:1).

Simulations: Combustion Chamber Volume is re-defined from 0°TDC to 120°ATDC

We anticipate this discovery will have a big impact on the future of GHG emission control in government policies, and will benefit the development of future transportation systems.

With 50% GHG reduction in emission, with doubled mileage in per gallon fuel and 50% reduction in weight and material, after 150 years of its initial invention, the piston engine will again reshape the energy landscapes.

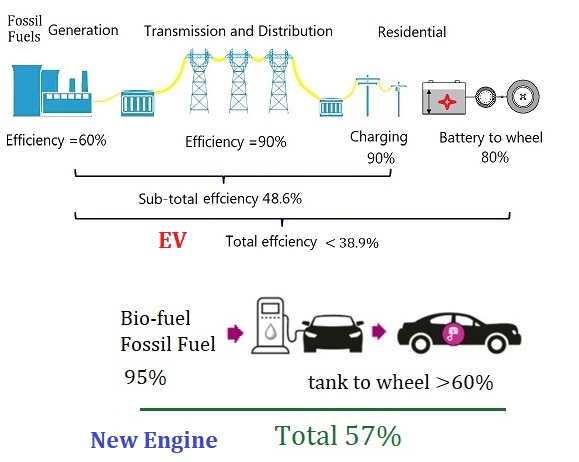

When the comprehensive total GHG emission of a new solution is lower than that of electric vehicles, the overheated electric vehicle development may have to take a detour. It is doubtful that electric vehicles are greener than traditional vehicles even at present gas-mileage rate because the high GHG emissions in battery related manufacturing and recycling. And many more factors, such as hazardous pollutions in making battery and high power IGBTs, and non-GHG impacts on environment in mining and semiconductor processing, have not been taken into detailed evaluations.

One gallon of ethanol in the new engine will cover 1.5 times mileages in comparison with one gallon of gasoline in an incumbent engine. Almost any kind of bio-fuel can be used in the new engine.

Direct constant torque control is available in the new engine, that means full driving torque can be obtained by controlling fuel supply at speed from 200rpm to 2,500rpm, the traditional multi-stage transmission can be reduced or eliminated in the new system, the new engine and powertrain are less than 30% in weight in comparison to that of a plug-in motor-battery system at a cruise range of 600 miles.

EV (battery powered electric vehicle) is not as green as we thought

Read more about the new Engine (PPT file)

Note 2, PPT file. More comparisons: from GHG to cost, the novel engine VS different solutions.

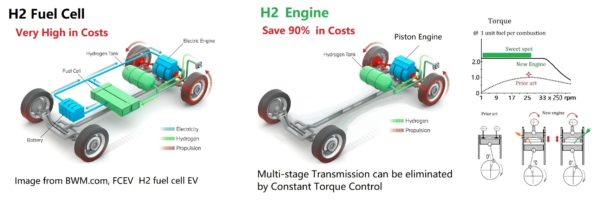

Hydrogen Engine or H2 Fuel Cell?

Zero-Emission Solution for automobiles.

Canada is one of the top 10 hydrogen producers in the world today. An estimated three million tonnes are produced per year from natural gas (mainly CH4). Canada is home to the largest clean hydrogen production facility in the world to produce hydrogen from natural gas with carbon capture and permanent storage for the resulting CO2 emissions.

The novel engine achieves its best potentials when burns H2: fuel efficiency is higher than H2 fuel cell (50%) and the cost of engine is only 1/10 of H2 fuel cell based power-train.

Benefited from its fast flame speed (two times faster than gasoline in combustion), H2 engine can run at constant torque from 200rpm to 6,000rpm, while the torque is constant from 200rpm to 2,500/3,000rpm for gasoline.

The new technology is a game changer for automobile power-train: torque on wheel can be controlled by fuel supply without switching multi-stage transmission gears, this dramatically reduces the cost and weight of automobiles.

Passenger car will stay as it is in next 50 years, the only uncertainty is what fuels we choose to burn: electric energy, gasoline, ethanol, nature gas or H2.

If we upgrade today’s fossil fuel passenger car to EV, the investment in infrastructure ( power supply and charging system) will be huge. And most countries just cannot afford the EV solution.

For upgrading to H2 fuel cell system, the cost is even higher; the cost of H2 fuel cell powertrain is almost 10 times of gasoline burning powertrain.

The novel engine can burn gasoline, and the engine can be switched to ethanol or pressured H2 by only replacing fuel tank and fuel injection or pump system, or simply keeps two fuel systems at same time. This will dramatically reduce the costs in transition from fossil fuel to any clean energy. The H2 engine is the best solution to make the fuel transition smoother and affordable.

The Challenge of Going Green is more than just cost

Read more at Natural Resources Canada, The Hydrogen Strategy 2050

PDF file: The Hydrogen Strategy, A Call to Action, by Natural Resources Canada.

What is the difference? The new engine VS Toyota 1NZ

For more information, please contact us at

(pistonICE (at@) dynamicbrake.com)